Funding Phase I

In contrast to standard fiber-reinforced matrix systems, the application of fiber-reinforced compounds with additional features in the field of lightweight construction is an unexplored area. The supplementary features, which are incorporated into the fibers, the fabric or the fiber core as well as the polymer matrix can be either of sensory or transparent nature.

The research project C04 strives for the fabrication of sensory and transparent fiber-reinforced composites.

For these purposes, the project C 04 addresses the following scientific questions:

- How can an additional sensory component be integrated into existing, fiber-reinforced compounds?

- In what manner is it feasible to produce transparent fiber-reinforced composites?

The sensory fiber-reinforced composites need to have appropriate mechanical strength, show the ability to detect small deformations or a partial failure of the composite and must allow data acquisition including subsequent information transfer. In addition, the sensory structures aim at a continuous detrection and quantification of mechanical stress in form of an electronic signal.

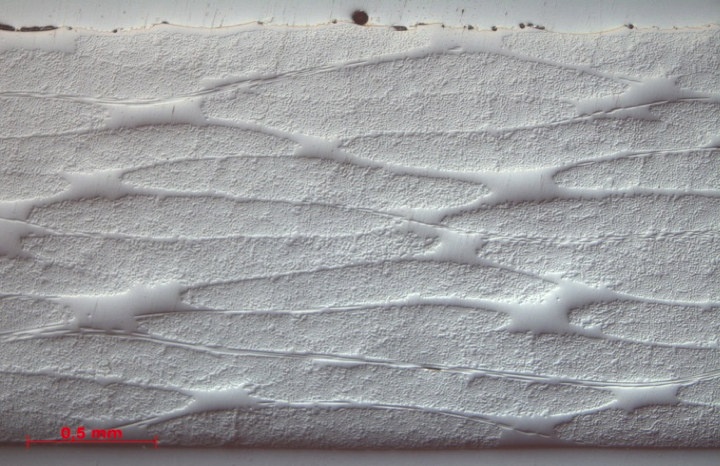

The integration of an additional sensory component into a fiber-reinforced compound can be realized in two different ways. The first entails the printing of conductive paths, structures or piezoelectric materials on the surface of fiber cores or fabrics via inkjet or silk screen printing. This method allows the spatial detection of conductivity or (capacitive) electrical resistance within the composite while the electrical signals change once mechanical stress is applied. Alternatively, the polymer matrix surface of the fiber-reinforced compound can be modified via silk screen printing using conductive structures.

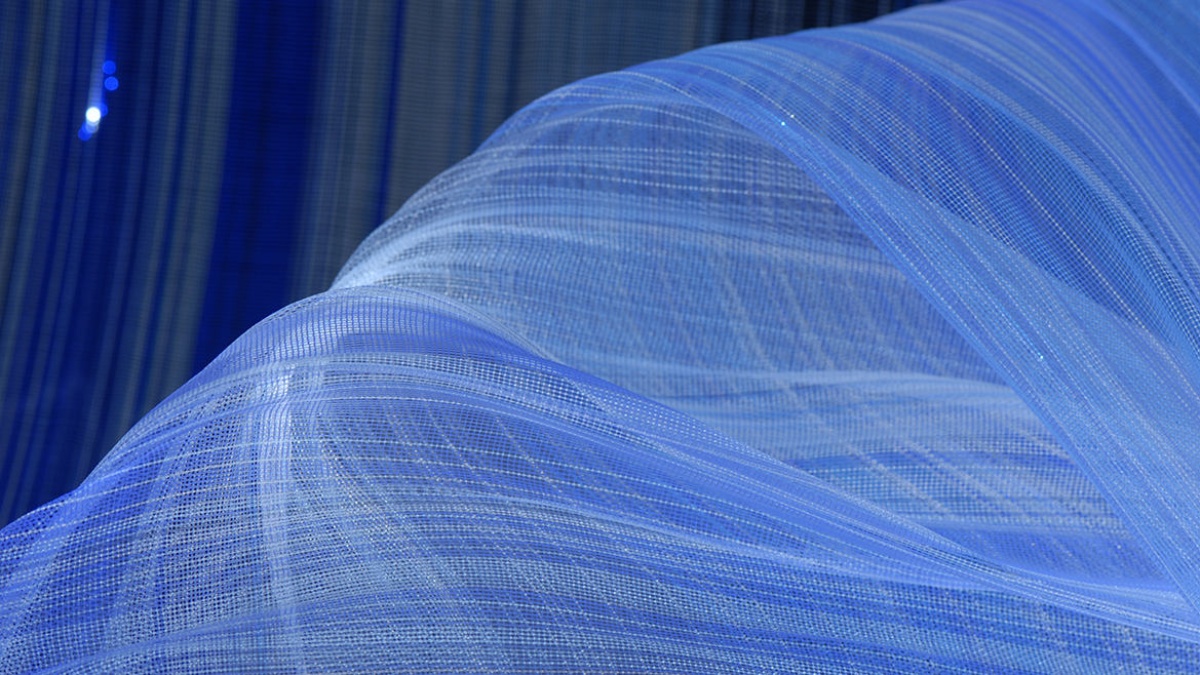

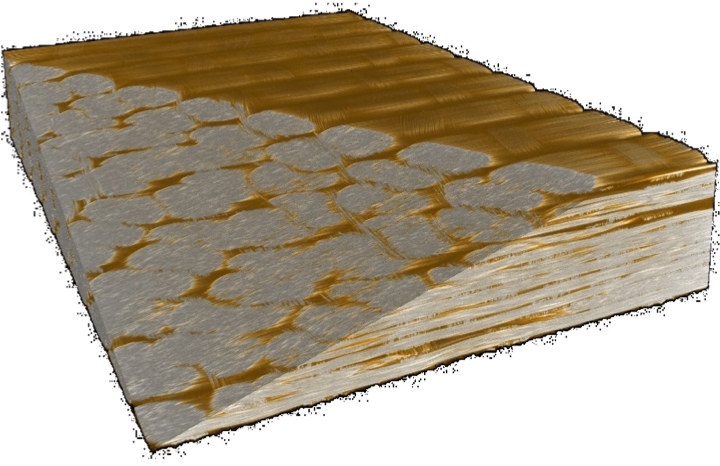

Another goal of the research project is based on the production of transparent fiber-reinforced composites, which would improve the mechanical resilience of façade structures in the visible range. For these purposes, the implementation of these transparent materials requires the adjustment of the refractive indices with regards to the thermosetting polymer matrix and the fiber material. Besides, the project aims at creating a semi-crystalline matrix showing small crystallite diameters or at completely amorphous matrices to provide full transparency.

Project C04 depends on a close cooperation with a large number of other projects within the CRC 1244 in order to accomplish the goals of both the project and the entire CRC. For instance, project D02 will be delivered with process related facility-specific data.

Subproject Leader

- Prof. Dr. rer. nat. habil. Michael R. Buchmeiser, Institute of Polymer Chemistry